Turbine

Department

Industry

Department

Oil & Gas

Department

Turbine

Department

Industry

Department

Oil & Gas

Department

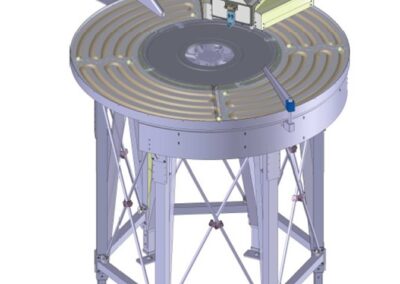

Following a number years of experience in hydroelectric industry, MTI offers completesolutions for your new turbines facilities, and also for the maintenance of your equipment.

Thanks to its know-how, its experience and qualifications, MTI collaborates with various industrial customers : railway industry, aeronautics and space industry, naval industry, energies and agro-food industry.

For a number of years now, MTI has been working for oil industry. Today, we have the full experience allowing us to position ourselves as experts to manufacture your items.

Thanks to different qualifications and production and control means, we are able to ensure the best quality in your project execution.

Following a number years of experience in hydroelectric industry, MTI offers complete solutions for your new turbines facilities, and also for the maintenance of your equipment.

Thanks to its know-how, its experience and qualifications, MTI collaborates with various industrial customers : railway industry, aeronautics and space industry, naval industry, energies and agro-food industry.

For a number of years now, MTI has been working for oil industry. Today, we have the full experience allowing us to position ourselves as experts to manufacture your items.

Thanks to different qualifications and production and control means, we are able to ensure the best quality in your project execution.

01 – Turbines

02 – Oil & Gas

03 – Industry

Mécanique &

Travaux industriels

MTI is a subsidiary of Figeac Aero group, and has implanted the market in 1994.

Specialized in Mecanics and industrial works, MTI provides high-performance solutions for tailor-made projects.

Activities & Skills

Mecanical and hydraulic sub-assemblies

Each turbine is a unique machine and needs to be very precisely designed and manufactured, assembled and installed on site with extra care.

Machining, metal work and welding

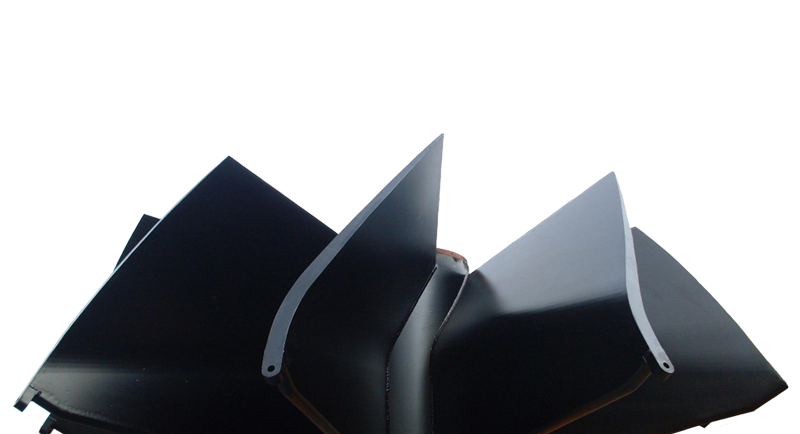

The MTI company is specialized in large dimension machining of unique pieces or small series with all sorts of shapes and profiles.

Assembles and on-site installation

MTI team is qualified to insure the correct assembly conditions and the final assembly of the complete equipment, pre-assembled inhouse.

Quality control and certifications

In order to validate the quality of our products, we use adjusted methods of control. All controls are done by COFREND II certified personnel, with certificate of conformance delivery.